Ethiopia, a nation steeped in history and culture, is becoming more and more acknowledged as one of Africa’s manufacturing powerhouses. With a population of over 125 million and a prime position in the Horn of Africa, the country has a lot of potential to become the continent’s most important center for manufacturing. Ethiopia is in the vanguard of Africa’s industrial development thanks to the government’s strong commitment to industrialisation, infrastructure investment, and special economic zones (SEZs).

Economic and political context

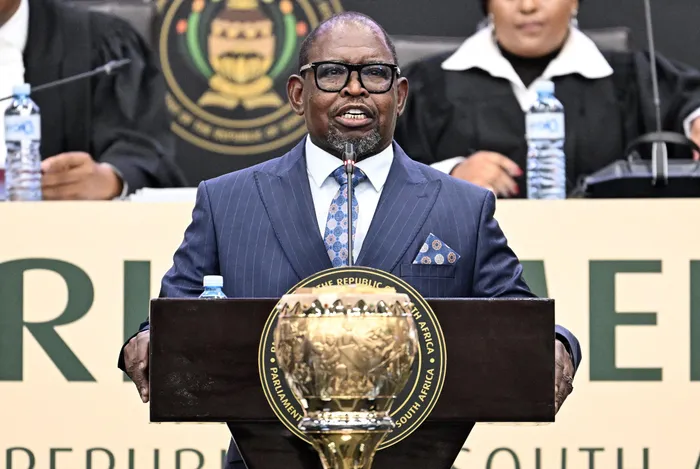

Under its Growth and Transformation Plans (GTP I and II), Ethiopia has been pursuing an aggressive industrialisation plan since the early 2010s with the goal of converting the country’s rural economy into one that is driven by manufacturing and industry. The administration has remained committed to economic reforms, especially in the manufacturing sector, despite political obstacles, such as the recent fighting in the Tigray region. The administration of Prime Minister Abiy Ahmed has persisted in giving economic reform, FDI, and infrastructural development first priority.

According to economic analysts, Ethiopia’s remarkable GDP growth rates over the last ten years, which have averaged about 8% annually, demonstrate the effectiveness of its economic policies. Initiatives like the Ethiopia Industrial Parks Development Corporation (IPDC), which has managed the development of multiple industrial parks throughout the nation, help the nation’s goal of becoming a center for light manufacturing.

Key drivers for economic growth

- Infrastructure Development:

Ethiopia has made large investments in energy installations, highways, and railroads in an effort to lower the cost of production and logistics. For instance, the Addis Ababa-Djibouti Railway increases export efficiency by connecting landlocked Ethiopia to the Port of Djibouti. Furthermore, it is anticipated that the Grand Ethiopian Renaissance Dam (GERD) will increase energy availability, resolving the ongoing power outages that have constrained industrial production. - Special Economic Zones and Industrial Parks:

Ethiopia has created a number of industrial parks with a focus on clothing, textiles, and agro-processing, including Hawassa, Bole Lemi, and Mekelle. Due to their strong infrastructure, simplified regulatory procedures, and tax benefits, these parks draw big businesses like Decathlon, PVH, and H&M. Ethiopia’s potential as a regional manufacturing hub has been strengthened by the parks’ performance. - Low Labor Costs and Demographic Advantage:

One significant advantage is Ethiopia’s youthful and plentiful labour supply. Ethiopia is a desirable location for labor-intensive manufacturing because it offers competitive production costs and wages that are far lower than those in China and Southeast Asia. Additionally, the availability of vocational training programs guarantees a workforce with the necessary skills to satisfy the expectations of multinational manufacturers. - Government Commitment and Policy Framework:

The government’s vision is guided by policies like the Homegrown Economic Reform Agenda, which emphasises macroeconomic stability, job creation, and industrial growth. Moreover, Ethiopia’s African Continental Free Trade Area (AfCFTA) membership provides access to larger markets, enhancing the viability of mass production for both regional and global export.

Challenges and Mitigation strategies

Ethiopia’s manufacturing sector has potential, but it faces obstacles like political instability, logistical inefficiencies, and inconsistent power supplies. To address these problems, experts recommend modernizing logistics networks, securing energy infrastructure, and diversifying the industrial base beyond textiles to include electronics and automotive manufacturing, which could lessen reliance on a single sector.

Comparative advantages over other African hubs

Ethiopia stands ahead due to its cost advantages and smart government initiatives when compared to manufacturing hotspots such as South Africa and Nigeria. Despite having a better developed industrial base, South Africa has much higher labour expenses. Nigeria, on the other hand, faces political instability and erratic electricity supplies. Ethiopia has made targeted investments in SEZs and infrastructure, creating a more stable environment for the expansion of manufacturing.

Recommendations for Sustainable Industrialization

- Strengthening Human Capital:

Putting money into education and career training will guarantee that workers are well equipped to meet changing industry demands. - Enhancing Political Stability:

Instability and war risks will be decreased by political inclusivity and long-term peace accords. - Improving Supply Chain Efficiency:

Ethiopian manufacturing will become more competitive by fixing energy problems and improving the logistics network. - Diversifying the Manufacturing Portfolio:

Expanding into industries like electronics and automobiles from textiles can increase market reach and resilience.

Conclusion

Although there are obstacles to Ethiopia’s rise as Africa’s manufacturing center, the nation’s strategic policies, demographic advantages, and continuous infrastructure development provide a solid basis for success. Ethiopia can achieve its goal of becoming the continent’s foremost industrial powerhouse by resolving logistical and political challenges. The ability of Ethiopia to maintain and grow its industrial trajectory could very well determine the future of African manufacturing.